Wet lamination of microfibrillated cellulose

Moving towards all-cellulose packaging materials

- Develop the barrier properties of a paper/board by MFC deposit

- Produce an all-cellulose barrier material that is bio-based, recyclable and biodegradable

- Evaluate the barrier performance of MFCs

- Assemble a thin MFC film with a paper or board using a filtering, replication and drying process at laboratory or pilot scale

Generate Value...

The packaging market is flourishing, and there is a need to develop new barrier materials that are renewable, recyclable and biodegradable.

Wet lamination of microfibrillated cellulose (MFC) is a unique process developed and patented by the CTP enabling a thin layer of MFC to be applied without glue to papers or boards in order to give them barrier properties and increase their stiffness, while preserving paper biodegradability and recyclability.

This process provides a means of forming an all-cellulose barrier packaging.

The CTP’s Functional Products division will draw on its extensive experience in developing the barrier properties of papers and boards and implementing various MFC grades to help you develop barrier materials using the MFC wet lamination process either on its own or in conjunction with other processes.

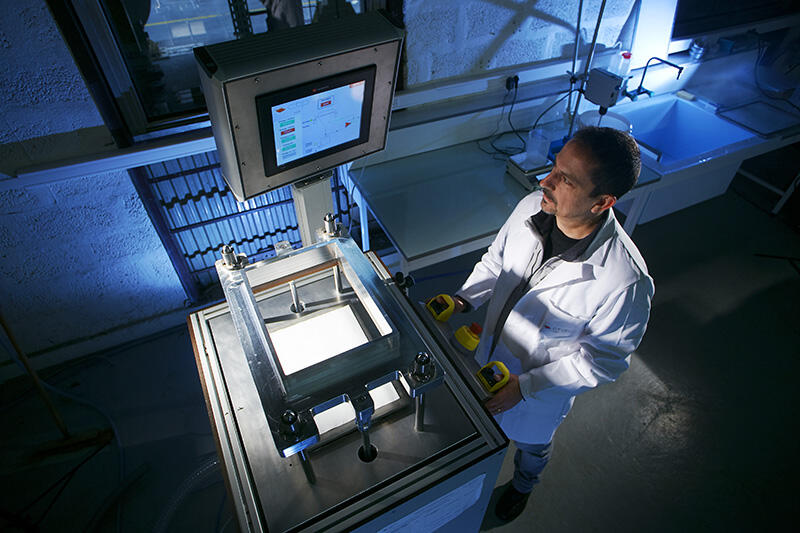

Wet lamination of MFCs at laboratory scale

Context and performance

Over the past five years the CTP has developed the MFC wet lamination technology at different scales, and now has the capability to apply a continuous MFC film on the surface of papers and boards.

The process is based on three stages: producing a wet MFC film using a paper-maker’s filtering process, replicating the film on a dry paper/board substrate, and lastly drying the assembled material.

Wet lamination of MFCs at pilot scale

Content of services

The CTP’s experts help companies to select the paper and board substrates and grades of MFCs and additives to be used, and to define and implement a test programme.

The CTP proposes tests at different scales:

- A laboratory-scale process to produce samples in A4 format in order to deliver proofs of concept and validate the approach taken and the performance levels obtained.

- Since autumn 2020, a pilot-scale process to laminate rolls and get closer to industrial conditions.

The CTP also proposes a range of paper pretreatment processes (precoating, plasma activation) to boost adhesion of the MFC coat, and post-treatment processes (coating, chromatogeny) to develop specific barrier properties. The CTP’s services also include the characterisation of MFCs and paper/board substrates, and evaluation of the performance of the laminated samples produced (mechanical and barrier properties, processing capability, recyclability, etc.).

Wet lamination pilot

Deliverables

The client is provided with a test report recording the operating conditions used for the tests and all relevant comments regarding their implementation along with the laminated samples in the form of rolls or in the format required.