Bonding, sealing and gluing

Paper/board bonding, sealing and gluing phenomena

- Perform various bonding tests and characterise the performance of your materials

- Test different bonding methods suited to the substrate and the production facilities

- Characterise the performance of paper/board sealing operations

- Identify and evaluate various issues

- Formulate technical recommendations with a view to predicting industrial conditions

Generate Value...

Packaging is a fast-growing market in which many new materials are being developed, notably using renewable resources.

It is essential to characterise and advisable to opti-mise the bonding properties of these materials.

The Centre Technique du Papier possesses various facilities for testing and evaluating the main types of bonding currently found in the paper and board industry.

The services it offers may include help in defining the most appropriate tests and operating conditions for each sealing method.

Thanks to such studies and the CTP’s expertise, you can:

- Optimise production parameters on your conditioning lines,

- Improve the performance of your sealing operations,

- Solve the associated problems,

- Speed up your product development.

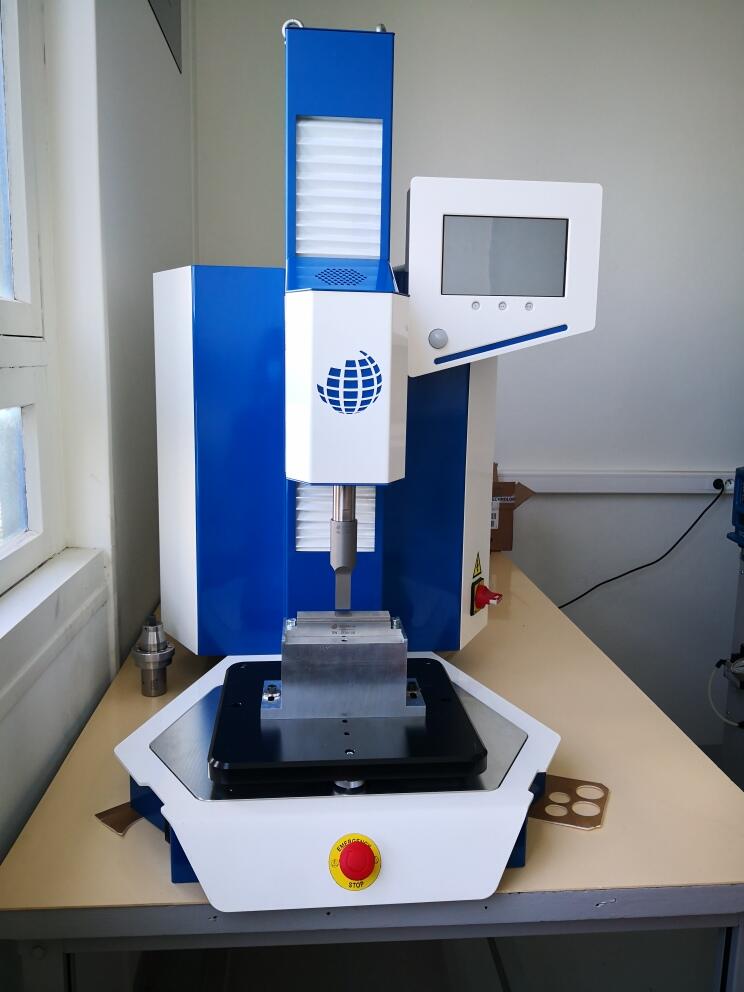

Ultrasonic press

Ultrasonic press

Context and procedure

The CTP offers a complete range of tests for charac-terising the main types of bonding, using standard or customised methods adapted specifically to market requirements.

Heat sealer

Content of services

To meet your requirements in full, a wide range of papers and boards can be tested on each facility:

- Ultrasonic welder for ‘sealing without glue’

In 2021 the Centre Technique du Papier acquired an ultrasonic welder designed by Nonimat, named ESW 2020. A wide range of settings for various papers and boards can be proposed thanks to different anvils, sonotrodes and boosters. - Heat sealer for ‘sealing without glue’

Many operating conditions and settings can be adjusted for this equipment, such as pressure, temperature and sealing time. Peeling tests can be carried out in line using a machine fitted on to the heat sealer. - Pilot gluing bench

This is used to perform tests with different types of glue (hot/hot-melt or cold/aqueous). The test samples obtained in this way are pressed in-line.

Cf. Pilot gluing bench data sheet

Pilot gluing bench

Pilot gluing bench

Interpretation of results:

- Peeling tests are performed on the test samples obtained in this way using an appropriate dyna-mometer in conditions defined with the customer in order to characterise assembly performance.

- In the event of inadequate bonding, further ana-lyses may be proposed in addition to the study, such as substrate wettability, glue penetration, and glue-substrate interactions and interface.

Deliverables

The CTP can provide a complete study report describing and interpreting the tests and the results obtained.