Services

Testing Laboratory

Internal bond - Peel - Pick

Bonding strength of paper and board

- Quality control

- Testing according to current French, EU and international standards

General informations

During manufacture, converting and use, paper and board is subject to a number of stresses that affect its surface, its fibre network, and/or the interface, in the case of composites, and can result in partial or total degradation of its structure.

A variety of methods can be used to characterise:

- Internal bond strength of papers and boards

- Peel strength of sealed or glued assemblies and labels.

- Picking resistance of paper and board surfaces

Technical Data and Achievements

Several standards and methods can be implemented, depending on the aim of the tests:

Characterisation of surface:

- Surface strength – Dennison wax pick test, according to the TAPPI T459 method

- Picking resistance, on an IGT printability tester with oil or ink, in accordance with ISO 3783

Characterisation of internal structure:

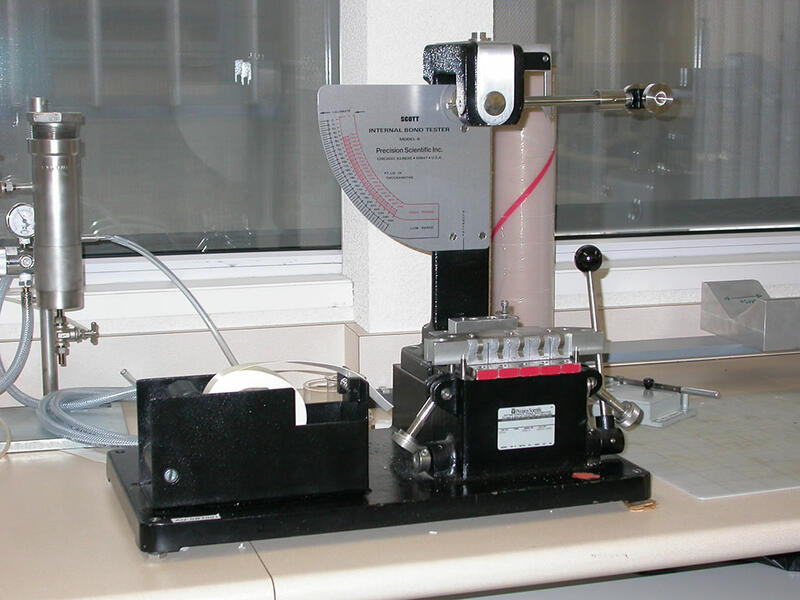

- Measurement of internal bond strength on a Scott Bond tester, according to the Tappi T569 method

- Z-direction bond strength, using a Frank-PTI burst tester according to NF Q 03-046

- Delamination strength of solid fibreboard, Hawkins method, ASSCO method no. 15

Characterisation of interfaces – glued and welded joints:

- Peel adhesion at 180°, using FINAT Test Method FTM No. 1

- Peel adhesion at 90°, using FINAT Test Method FTM No. 2

- Low-speed release force, using FINAT Test Method FTM No. 3

- T-peel test, fixed or unfixed, in accordance with various standards

- Floating roller peel resistance, using ASTM standard D3167

|

|

|

| Scott Bond Tester |

Also to be seen

Consultancy Diagnosis

Centre of Excellence

Testing Laboratory

Laboratories

Collaborative projects