Folding and creasing

Expertise dedicated to brochures and compact board boxes

- Assess problems of cracking at the fold on printed media such as brochures and magazines

- Define creasing conditions for optimum folding on folding box and carton conditioning lines

Generate Value...

Cracking at the fold is a recurrent problem. It leads to many costly disputes between paper makers and printers. It is generally due to a variety of factors that may occur at any stage of the production process.

The CTP can carry out an impartial technical appraisal, based on targeted measurements performed in the laboratory on samples taken at the various stages, making it easier for the parties to reach an agreement.

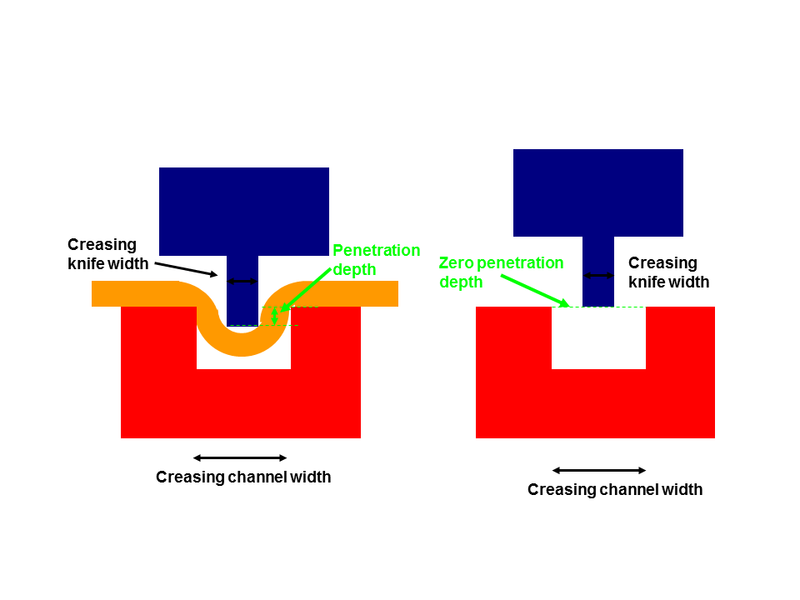

In the case of thick board and paper, the CTP’s expert appraisal focuses on selecting the optimum creasing conditions (in terms of creasing rule and die dimensions and penetration depth) in order to fold the material effectively without causing excessive damage. The CTP possesses a number of highly specialised facilities for performing this type of study.

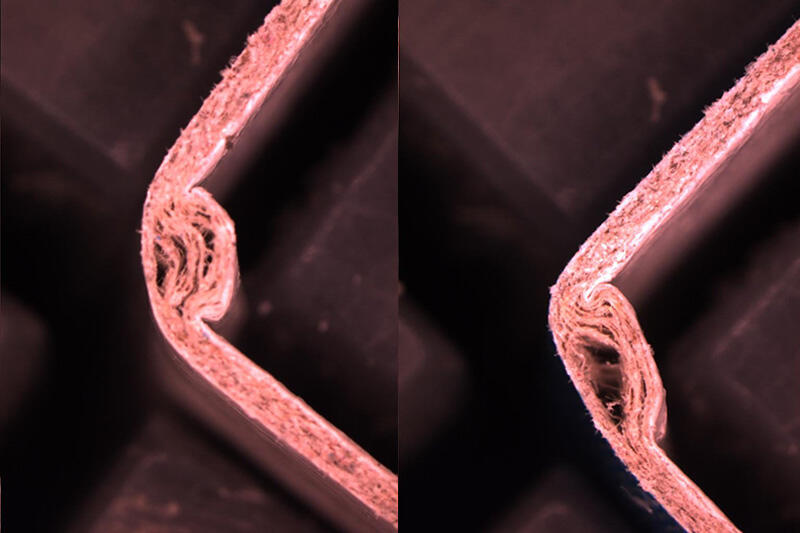

View of creasing bead bump delamination under high

magnification

Context and performance

The creasing studies performed depend on the context: optimisation of creasing on a new substrate, appraisal after a problem has occurred on the conditioning line, etc. To analyse a problem of cracking at the fold, the CTP will usually compare the paper in question with one of similar quality that has already given satisfaction.

Correct creasing bead bump /off-centre bead

Content of services

Depending on the client’s specific requirements, the CTP may propose the following tests:

To analyse a problem of cracking at the fold:

- Measurements of tensile strength and stretch. Ideally, the tests are performed on virgin paper, non-converted printed paper and converted (folded) printed paper.

- Folding in the laboratory in controlled, reproducible conditions and testing of tensile strength on folded samples.

- Determination of fibre composition and ash content.

To optimise creasing:

- Selection of creasing rules and dies depending on the grammage and thickness of the material.

- Creasing on a Patra press

- Cross-sectional photos of ply delamination

- Curves showing the folding strength of creased board using a Marbach device.

Additional tests on preformed folding boxboard (delivered flat):

- Determination of box opening resistance using a dynamometer.

- Dimensional characteristics of the creasing bump (height, depth, centring) using a creasing sensor.

Principle of creasing tests

Principle of creasing tests

Deliverables

On conclusion of the tests, a complete report is sent to the client, including the results, photographs, comments and conclusions. The origin of the problem of cracking at the fold may be identified in most cases (intrinsic fragility of the paper or dehydration due to storage conditions or over-drying).

Creasing studies are a means of seeking the optimum combinations for creasing the board effectively, or pf for checking the quality of industrial-scale creasing (measuring bump height and centring).