Printing and characterisation of RFID antennae

Assisting printers/converters in the production of RFID antennae

- Analysis of the possibilities for producing RFID antennae available using the company’s resources

- Choice of technologies (type of antenna, chip, etc.) depending on the specifications defined beforehand

- Printing of RFID antennae

- Assistance in the choice of chip transfer technology

- Presentation of the possibilities for the testing/encryption of tags

Generate Value...

The RFID market is growing rapidly. Although it has existed for more than 80 years, the number of tags on the market has rocketed in the last 10 years thanks to the use and development of UHF tags in logistics, and to the use of HF (NFC) tags right down to consumer level. More and more RFID tags are being integrated into objects used in daily life, giving them more added value and opening up new markets.

Traditional printers/converters are thus seeing demand increasing for integration of these objects into printed materials, which is also diversifying their client base.

Most of the tags are manufactured in China and then transferred to different substrate. Thanks to its expertise in electronized print, the CTP offers printers/converters the possibility of developing their own tags and integrating them, without major modifications, into their production facilities.

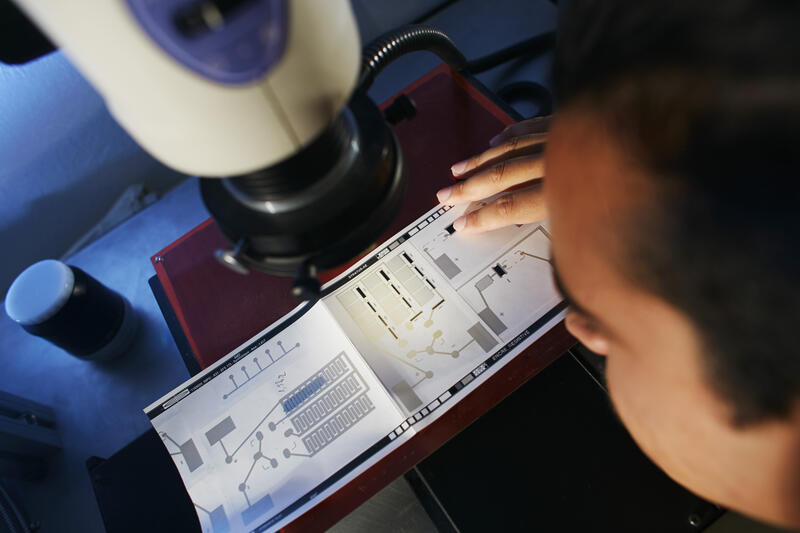

Study of antennae in the laboratory

Context and performance

Thanks to various initiatives such as the EIPIT” project, the CTP has put in place unique resources for antenna design, laboratory and industrial printing, and chip transfer in conventional printing processes. These are necessary because the theory of antennae for paper electronics differs from that used for traditional electronics. Printing of RFID antennae therefore requires specific knowledge that the CTP has been acquiring and developing since 2008.

RFID for logistics

Content of services

Support for companies with the implementation of RFID tag production consists of several stages:

- Expert appraisal and audit of the industrial production workshop in order to validate the feasibility of the project.

- Definition of the functional specifications of the antennae in collaboration with the company.

- Choice by the CTP of the antenna design and the associated chip technology corresponding to the specifications

- Expert training for staff in the specific practices associated with paper electronics

In some cases, existing equipment may need to be optimised before the first industrial-scale test is performed. The CTP can support the company in performing the first production runs on its production site.

Decartag, a solution for board packaging

Delivrables

- Choice of the printing technology

- Design of the antenna in compliance with the defined specifications.

- Training of staff in best practices associated with paper electronics.

- Optimisation of the printing process in the context of paper electronics.

- Selection of a transfer technology in accordance with the specifications and the available resources.