Pilots

Multi-tank Moulded Cellulose Pilot

Production of innovative 3D cellulose objects

Production of innovative 3D cellulose objects

Chromatogeny Pilot

A breakthrough technology for hydrophobic papers & boards...

Develop hydrophobic paper and board that can replace plastics fully recyclable and biodegradable.

The MFC wet lamination pilot

Paper and board covered with microfibrillated cellulose for barrier packaging

Develop paper and board laminated with MFC for the packaging and specialty papers sectors

Foam generator

Lignocellulosic foams, deposits in foam

Generation of foam in situ, within a particle suspension

Pilot of BIVIS extrusion

Fibres, MFC, molecules

To produce fibres or microfibrillated cellulose (MFC) at high consistency

NaMiCell pilot

Production of microfibrillated cellulose (MFC)

To produce MFC from different qualities of pre-treated lignocellulosic fibres

Bleaching / Fibres Functionalization pilot

Simulate your processes to reduce costs and / or environmental impact

To simulate in a reproducible and reliable way all the bleaching stages and the functionalization reactions of lignocellulosic fibres

Pilot gluing bench

Evaluation of paper/board gluing performance

Characterise paper/board gluability

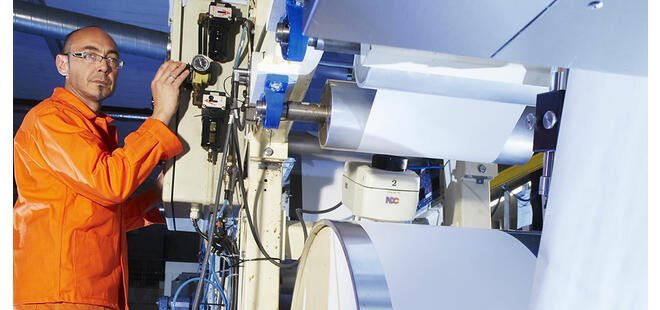

Coating Pilot

Paper and board coating for graphics, barrier and speciality applications

Develop coated paper and board for printing and writing, packaging and speciality markets

Recycled Fibres Pilot

A unique and essential tool for recycling and deinking

- Prepare recycled or deinked pulp at semi-industrial scale

3D SPRAY PILOT

Coating/functionalisation of 3D cellulose objects for packaging and speciality applications

Develop coated 3D cellulose products and objects for packaging and speciality markets

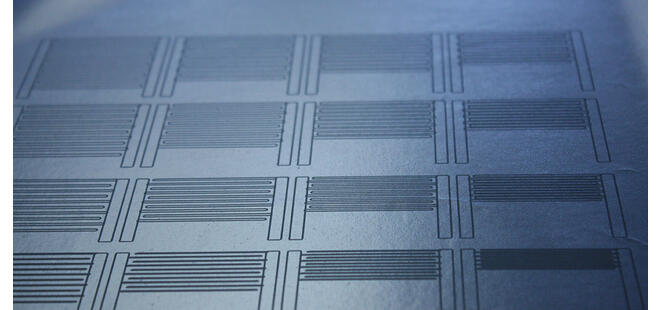

Laser surface abrasion

The “Swiss Army knife” of paper electronics

In-line cutting, In-line digital abrasion, Welding of electronic components

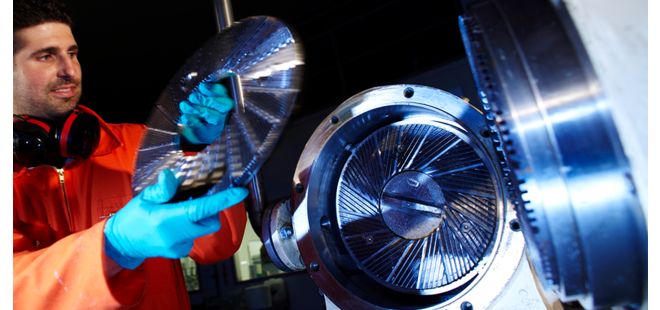

Refiner mechanical pulps production pilot

RMP, TMP, CTMP, APP

- To simulate the mechanical pulping processes based on disks refiners (in industrial conditions)

Molecules extraction and unbleached chemical pulps producing pilot

Multipurpose valorisation of lignocellulosic raw materials

To extract molecules present in lignocellulosic raw materials

Production of Technical Lignins

Kraft, soda and hydrolytic lignins

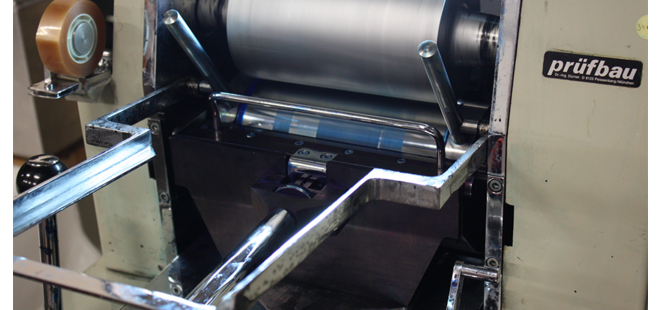

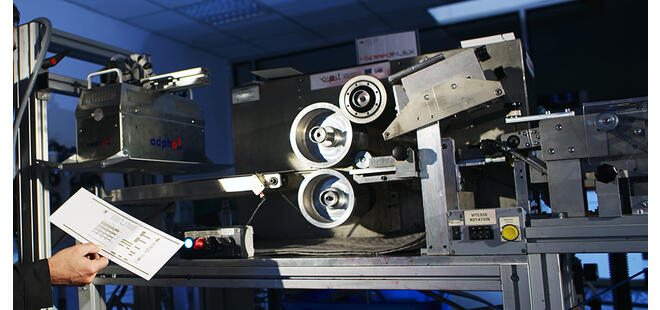

Gravure360, rotogravure printing

Multifunctional Rotogravure Pilot

Industrial speed printing

Pulp low consistency refining pilot

To reproduce at laboratory the refining used by industrial production mills

To produce batches of pulps to evaluate the impact of mechanical treatment on fibres

i-SpeedJET

Adaptation of inkjet printing to the industrial scale

High-speed inkjet printing (direct marketing, newspapers, packaging, etc.).

Fractionation pilot platform

Unique facility under one roof to produce distinct fractions

Operational flexibility, large capacity of fractions generation...

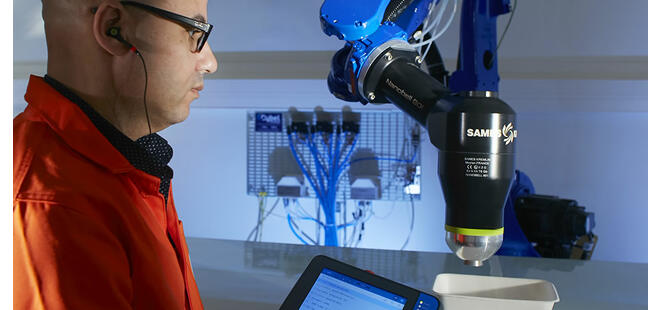

PAPRIKA: the four-axis robot

High-precision hybrid paper electronics

Handle electronic components

JEEP: inkjet printing

Jetting Electronics Elements Pilot

Inkjet printing pilot

ScreenInk: screen printing

A tool to reproduce your industrial prints in short production runs

Print on all substrates

I-SpeedFlex: flexographic printing

A tool to reproduce the speed, flexibility and print quality of your industrial printing

Reproduce industrial conditions