Optibox

Corrugated board packaging design software

- Choose the right board quality to be used in corrugated board packaging thanks to Optibox, a relevant decision support software

- Best meet the requirements of the Packaging Directive 94/62/EC

- Optimize raw material costs (corrugated board)

Generate Value...

Packagings placed on the market must meet the requirements of the Packaging Directive 94/62/EC and particularly the requirement for design, manufacture and composition to prevent waste reduction at source as described in NF EN 13428. So far, packaging must be designed and manufactured in such a way as to limit its volume and mass to the minimum while ensuring a good enough level of safety, hygiene and acceptability, both for packaged products and for the consumers.

The cost of the raw material (corrugated cardboard) represents 40 to 60% of the cost of the packaging, a significant part. Then adjusting board quality becomes an important competitive advantage for packaging manufacturers and users.

Optibox can be used from a web page and by subscription from any computer, tablet or smartphone. The study may be carried out by the CTP or independently under license to operate on request.

Visit the tool: www.optibox-online.fr.

Context and performance

The Optibox software is owned by CTP and was developed in collaboration with the Cartonneries de Gondardennes (CGW) and CAP (Association of Cardboard and Paper articles, including the converting ondustry).

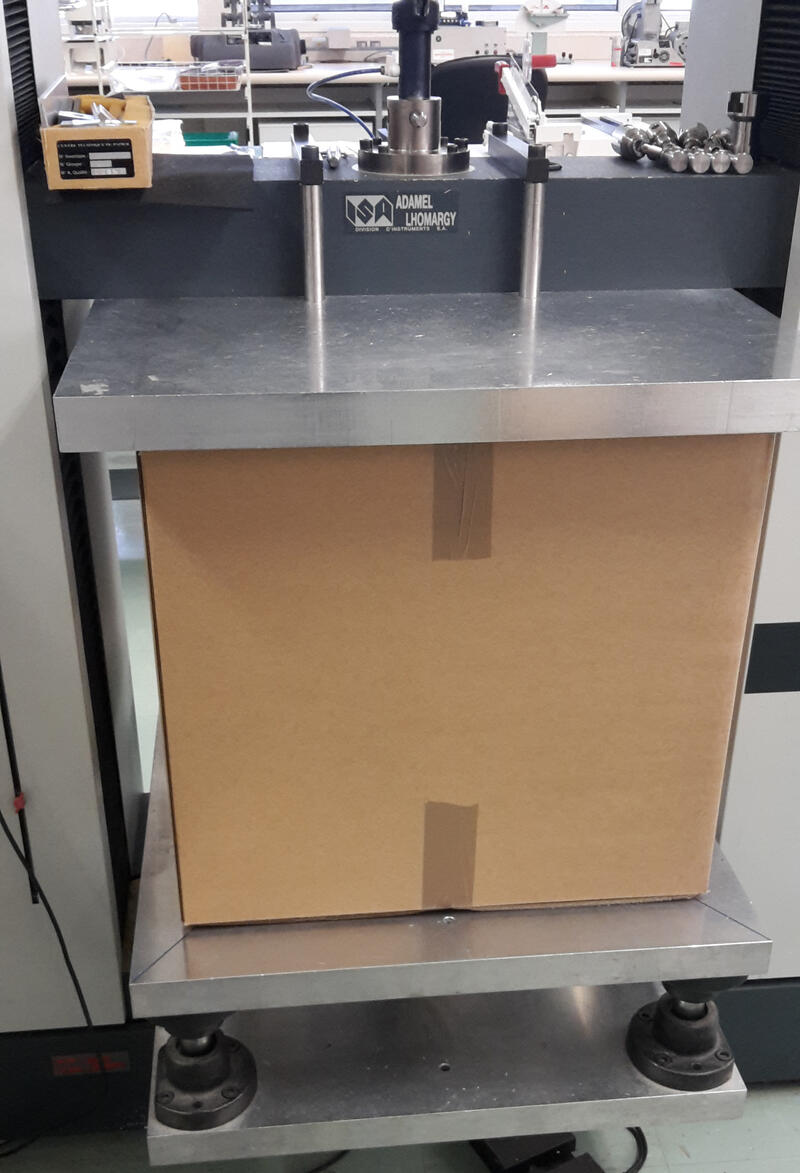

Optibox is a decision support software that helps for choosing the quality of the corrugated board (in terms of ECT - Edge Crush Test Value) to be used for a given level of BCT - Box Compression Test Value of the packaging.

The required level of BCT is assessed on the basis of the usage conditions and shall take into account input data relating to the description of the packaging, the content, the palletizing pattern and the transport and storage conditions.

Content of the service

A form is to be filled by the customer with the relevant input data. Upon receipt of the completed form and after verification of the consistency of the transmitted information, the input data is implemented in the software and an evaluation of the required ECT is obtained for the different fluting profiles available in the tool: double-sided profiles E, D, B, C and double-waved profiles ED, EB, DC and BC.

As the tool was developed with the support of the Cartonneries de Gondardennes, the software also proposes the corrugated board grades available at CGW, together with their thicknesses, their average levels of ECT, their composition and their carbon footprints (direct and indirect emissions).