Measurement of fibre flocculation

Benchmarking of retention systems using flocculation measurement

- Investigate the most appropriate retention systems

- Measure fibre flocculation: a dedicated sensor developed by the CTP

- Results that can be transposed from the pilot to industry

Generate Value...

If you are wanting to optimise the use of your retention system, the CTP proposes a comprehensive service based on the application of an original procedure, namely measuring fibre flocculation in the suspension.

The sensor is used to carry out various studies on the wet end:

- Evaluation of the flocculation capability of different fibres, depending on their morphological properties (length, flexibility, etc.), their concentration, and shear.

- Benchmarking of retention systems

- Optimisation of doses of wet end additives, of their point of introduction, etc.

It can be combined with retention measurements in order to achieve the best compromise between flocculation and retention.

The facility can be used to select the fibre composition that ensures minimum flocculation (and thus guarantees optimum formation), and to select the best retention system, i.e. to obtain a given retention level while at the same time minimising the impact on sheet formation. For example, in the case of a fibre composition for a virgin pulp-based printing paper, the pilot study demonstrated the advantages of a micro-particle system in this respect. It is then possible to determine the optimum technical and economic solution to limit the consumption of retention agents.

Context and performance

A very wide range of products are offered by retention agent suppliers: polymer systems, simple or dual polyelectrolytes, and polyelectrolytes with associated microparticles. There is thus a real need to compare the performance levels of these various retention systems in conditions similar to those in the short circuit of a paper machine.

Fine elements are retained by a flocculation mechanism. Such poorly selective flocculation also applies to the fibres, and this undermines the quality of sheet formation. When testing the performance of a retention system, it is therefore crucial to measure its effect on fibre flocculation at the same time. The selectivity of the flocculation process depends on both the retention system and the conditions of use.

Flocculation sensor

Content of services

- Pilot study on the pulp circulation loop.

- Measurement of fibre flocculation.

- Simultaneous physicochemical measurements: retention, drainage, zeta potential, fibre flocculation. Your own fibre composition is used.

- Injection of additives, reproducing the conditions found in your own short circuit (points of introduction, contact time, shear intensity, etc.).

- The system is original in that it measures flocculation in an unmodified industrial environment, with the sample not undergoing any dilution.

- Possibility of measuring flocculation in-line, in order to check the recommendations derived from the pilot study.

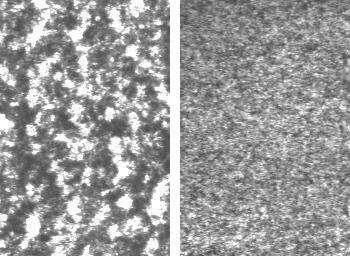

Measurements ranging from dense to light flocculation

Delivrables

- Visualisation of the state of flocculation of the suspension

- Flocculation index correlated with visual impression

- Quantification of the trade-off between retention and flocculation

- Recommendation regarding choice and operation of retention system

- Optimum technical and economic solution.