Formulation of functional ink

Design of printing press ink

- Formulate an industrial ink for evaluation in the laboratory or in industrial applications

- Integrate a new functional component into an ink

- Optimise an existing formulation

Generate Value...

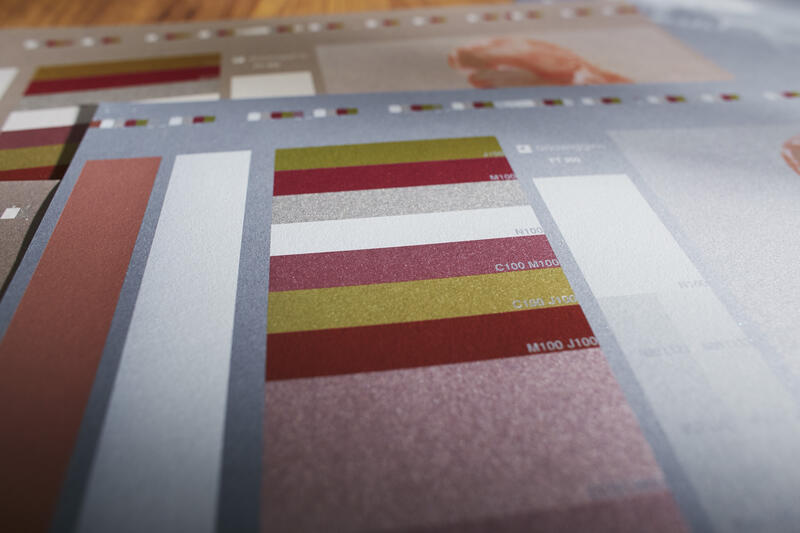

Functional printing is a new field that is opening up many new opportunities for the paper-making and printing industries. Graphic inks are being replaced by inks with functionalities that are not merely colour-related: electricconductive, resistive, luminescent, water- or grease-repellent, sealable, security, etc.

To achieve this, new active components need to be formulated and integrated into an ink so that they can be applied using conventional printing processes: screen, offset, flexography, inkjet, etc.

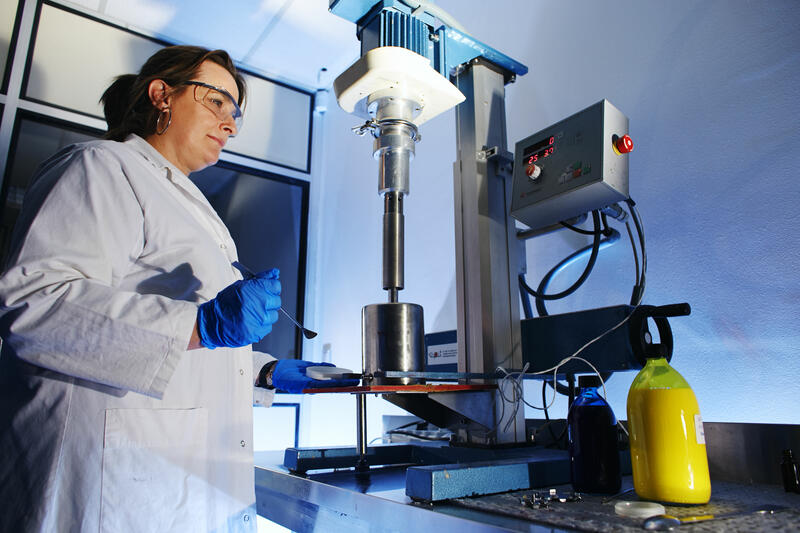

The CTP now has expertise underpinned by an ink formulation laboratory using mixing, dispersion or grinding techniques, for volumes ranging from a few tens of grams for laboratory tests to a few kilograms for industrial-scale evaluations.

Context and performance

The CTP has solid knowledge of commercially-available printing inks in terms of their formulations and the properties required, in particular rheological properties such as viscosity.

The formulation tools available at the CTP include a Dispermat dispersion and grinding system.

This multi-function tool can perform the following tasks:

- mix liquid components

- disperse soluble particulate components

- grind insoluble particulate components (using a bead mill)

Contenu de la prestation

- Client account management

- Study of the requirement

- Guidance regarding the formulation depending on the desired functionality, the printing process, the drying method and the subtrate.

- Formulation using tools available at the CTP for measuring quantities

- Rheological characterisation possible

- Control of formulations through laboratory printing or industrial-scale printing at a partner printer

- Characterisation of functional performance, and technical/economic evaluation

Possibility of printing the inks developed

Delivrables

- Ink samples and formulation recipes

- Characterisation and comments

- Testing report