Controlling stickies

A stickies assessment can improve productivity

- Identify the origin of disturbances caused by stickies

- Characterise sticky deposits using specific methods

- Quantify the stickies content of your pulp and the efficiency of your processes

- Make recommendations to improve processes by managing stickies

Generate Value...

Having trouble solving your stickies problems? With more than 45 years of research, 50 audited sites and its extensive database, the CTP is in a position to help you solve these problems.

Carrying out a stickies assessment on your process will enable you to analyse the overall efficiency and stage-by-stage efficiency of your process, while enabling you to compare it with similar productions contained in our database.

Identifying the type of stickies responsible for the disturbance will point you in the right direction : improved screening or better management of the wet end, depending on the type of stickies involved.

Implementing the most appropriate measures will result in productivity gains: fewer breakages, less soiling, improved paper appearance, etc.

Several thousand euros saved.

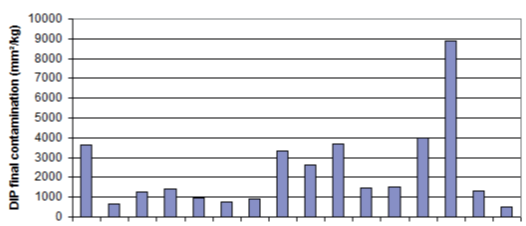

Contamination by macro-stickies, found in various paper mills, extracted from the database

Contamination by macro-stickies, found in various paper mills, extracted from the database

Context and performance

It is often difficult to identify the cause of disruption caused by stickies. Yet this is the key to implementing the most appropriate corrective solutions.

The aim of the assessments we offer is to help you understand the causes of the problems you are experiencing, and then to recommend the most appropriate ways of dealing with them.

Secondary stickies on machine canvas (G*100)

Secondary stickies on machine canvas (G*100)  Macro-stickies taken from De-inked Pulp (DIP) lines (G*300)

Macro-stickies taken from De-inked Pulp (DIP) lines (G*300)

Content of services

The service can be provided at several levels :

- Use FTIR analysis to determine the chemical nature of the particles/sticky deposits, and complete the analysis with a KAYENCE microscope.

- Quantify and categorise the macro-stickies by size using a laboratory screening method supplemented either by measurement using the appropriate INGEDE 4 method or using the 3DStick (morphology and nature of the stickies).

- Target the nature of the problem using a simplified assessment, with one sample at the process inlet and one at the headbox.

- Suggest improvements to the process using a complete assessment.

- Use a solvent extraction method for micro-stickies and colloids that cannot be recovered by classification.

Delivrables

At the end of the study you will have :

- Identification of the type of stickies causing the disturbance

- The overall level of contamination in your line, which can be compared with our database

- The overall efficiency of your line in eliminating stickies

- The efficiency of specific stages (grading, flotation, etc.)

- Recommendations for reducing the problems encountered. These recommendations can then be simulated on our PS 2000 platform to validate the technical and economic benefits.