Control of foaming in effluent treatment

Foaming measurement and defoamer effects in aeration tanks

- Measure foaming in effluents from industrial sites

- Determine the impact of foaming chemicals

- Optimise antifoaming solutions

- Measure antifoamers effect on oxygen transfer (KLa) and effluent purification

General informations

Foaming problems related with surfactants are frequently observed in effluents treatment plants of pulp and paper production sites. Defoamer used to reduce foaming may limit effluent treatment performances and oxygen transfer in aeration tanks. Oxygen transfer limitation leads to increased aeration capacity requirement and extra operating cost for power supply.CTP developed a protocol to quantify surfactant related foaming on one hand defoamer efficiency and impact on oxygen transfer in aeration tanks on the other hand. This method is also applicable to other paper additives impacting oxygen transfer in effluents.

Données Techniques et Réalisations

Characterisation of foaming and defoamer effects

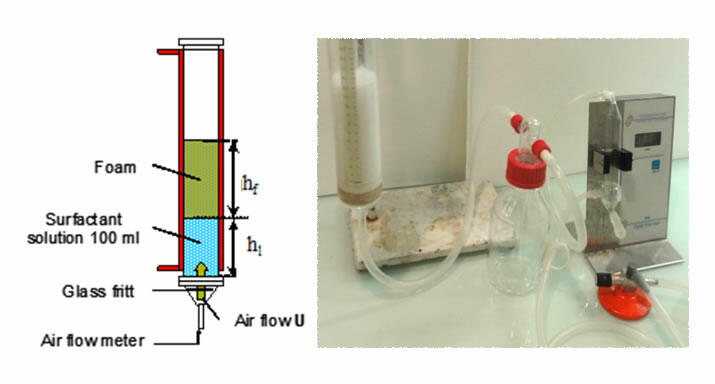

Experiments are based on Bikerman foaming test protocol, the principle of which is to evaluate, as a function of time, the volume of foam produced in a column during air bubbling in a solution containing the additives to be tested.

This test is performed at different concentrations of chemicals (surfactants, defoamers, others). The purpose is to simulate aeration conditions of aerobic treatment process.

Measurement of COD reduction

Defoamer chemicals may significantly increase effluent COD and limit treatment performance. COD measurement are performed to quantify the contribution of defoamers and reduction by biological treatment (refer to biodegradability testing and inhibition of oxygen uptake rate by activated sludge).

Measurement of oxygen transfer coefficient (Kla)

Dissolved oxygen is removed from effluent by nitrogen bubbling. Air is then injected into the samples under controlled conditions (T°, stirring, flow rate).

During air introduction, recording of dissolved oxygen value allows to determine oxygen transfer coefficient (KLa).

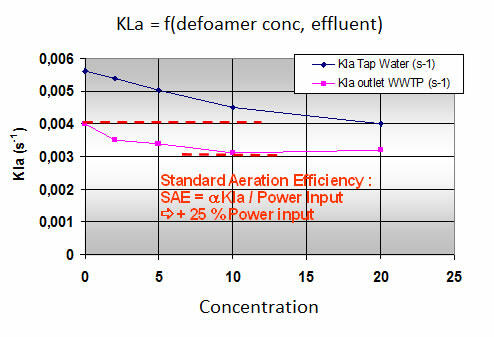

Kla measurements are realized with different chemical additives concentrations (surfactants, defoamers, others). decrease in Kla value will require increasing aeration of activated sludge tank to maintain constant aeration since standard aeration efficiency is proportional to Kla and adsorbed power.

Combining foaming test results and COD or KLa measurements will allow to select efficient defoamer with reduced impact on oxygen transfer.

|

|

|

| Bikerman foaming test | Measurement of oxygen transfer coefficient (Kla) |