PhenoLiq (2017-2021)

Tailor-made Kraft lignins for the production of phenols

- To develop a multistage and continuous liquefaction process to produce phenols

- To set the specifications of lignins which are the most favorable

- To evaluate the integration of this new production unit in a kraft pulp mill

Aim of the project

Supported by ANR¹, coordinated by the Fédération J. Villermaux associating LRGP², LCPM³ and LERMAB⁴ laboratories and in collaboration with IRCE Lyon⁵ and CTP, PhenoLiq answers to these objectives for the future.

Indeed, 10 million tons of phenol are produced annually in the world, from petrochemical route. This is an important platform molecule of the chemical industry, for the production of resins and plastics. The lignin, a polyphenol complex and natural component of lignocellulosics, represents 20 to 30 % of wood. This is an important co-product of kraft pulp mills, mainly valorized as energy.

Due to their structure and availability, kraft lignins could be an attracting bio-sourced alternative for the manufacture of green phenols. This project aims to convert lignin in phenolic compounds by a thermochemical and catalytic process of multistage and continuous liquefaction, with the study of its integration in a pulp mill.

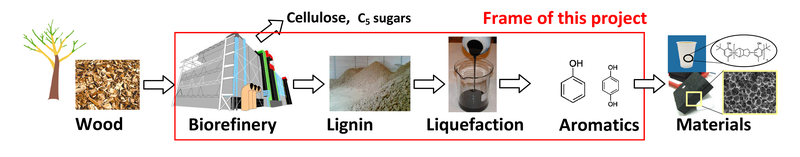

Phenoliq : from wood to bio-based materials through an existing pulp mill

Phenoliq : from wood to bio-based materials through an existing pulp millThanks to to an exhaustive characterisation of different technical lignins by CTP and its partners, and after some trials of catalytic deconstruction carried out by LRGP and IRCE Lyon, a typical profile of the ideal lignin was established. Some tailor-made production of softwood Kraft lignins issued from pulp mill black liquors were also designed and performed at laboratory and pilot scales (CTP’s lignin plateform). Based on the industrial data collected on a pulp mill site and thanks to measurements done on the pulp production line, the lignin extraction unit and the catalytic liquefaction process were modelled and integrated into those of the studied mill. Scenarii of production and converting were simulated, allowing establishing the first technico-economical balances for this new valorization way.

Our partners :

¹ ANR : Agence Nationale de la Recherche

² LRGP : Laboratoire Réactions et Génie des Procédés, Nancy

³ LCPM : Laboratoire de Chimie-Physique Macromoléculaire, Nancy

⁴ LERMAB : Laboratoire d'Etude et de Recherche sur le Matériau Bois, Epinal

⁵ IRCE : Institut de Recherche sur la Catalyse et l'Environnement de Lyon