Heat recovery

Reuse heat losses and reducing effluent temperature

- Measure the amount of available heat energy

- Quantify heat requirements and check that they are compatible with the available heat

- Model circuits to assess the impact of changes on the site and on effluent temperature

- Perform an economic assessment of the proposed solutions with the suppliers

Generate Value...

As the world becomes increasingly mindful of its duties to future generations, our actions when it comes to the environment have changed substantially.

Authorities are now imposing ever stricter laws and regulations limiting the temperature of effluents released into the natural environment.

Controlling energy costs and CO2 emissions is now a key issue for the paper-making industry.

In light of this, the CTP has developed tools and methods to measure and assess the heat energy requirements and sources available at a given production site. These services culminate in an action plan to reduce effluent temperature and recover heat.

One site producing 300,000t per year was able to generate savings of €60k per year by implementing our recommendations.

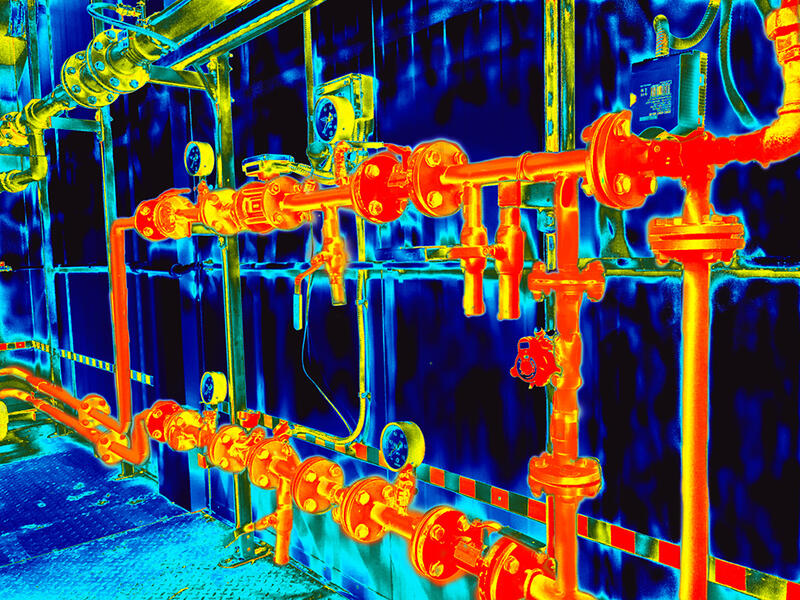

View of piping using a thermal imaging camera

Context and performance

Heat recovery spans a number of different issues: shutting down cooling towers, reducing the temperature of emissions (effluents and drying section exhaust air), part of a process requiring low-temperature heat, etc.

Drawing on its knowledge of heat energy uses in paper-making processes, the CTP is capable of performing studies specific to each configuration and proposing appropriate solutions.

Simulation of fitting a heat exchanger using the PS2000 simulator

Content of services

- On-site collection of data and measurements in order to characterise the available heat energy and potential heat requirements (internal or external).

- Analysis of the potential for heat recovery: identification of the best possible exchanges between a heat source and a heat requirement.

- Analysis of solutions: assessment of the impact of these heat exchanges on circuit temperatures in steady-state operation. This assessment utilises the CTP’s modelling and simulation resources.

- Technical and economic assessment of the solutions, based on discussions with equipment suppliers.

Example of a spiral heat exchanger at a paper-making site

Deliverables

A study report presenting, depending on the case:

- The specific context of the study

- The site constraints

- An assessment of the amount of available heat energy

- The potential for heat recovery

- The results of the process simulations

- A technical description of each solution

- A quantification of energy savings

- An estimate of investments and gross payback time.